Witness the Netherland’s Wijsman Cobblers Resole These Red Wing 699 Loggers

Anyone just slightly familiar with Rope Dye will know that in addition to denim we’re also big fans of leather boots. Recently, our Dutch photographer and major Red Wing enthusiast, Micheal van Hal, visited the certified Red Wing Repair Center for Benelux, Wijsman Cobblers, located in Delft in the Netherlands. He needed to get his vintage 699 Loggers boots resoled and caught the action on camera for you to enjoy in this two-part mini-series.

A 699 In Need of A New Outsole

Last year, Michael bought a pair of vintage 699 Loggers in a nice Black Boomer leather paying only 20 euros!

Up until then he had only worn Red Wings with the Traction Tread, Nitrile Cork, and Roccia outsoles; these Loggers were a little harder to get acquainted with – especially the height of the heel.

So they were put back in the box and Michael started searching for a solution.

Red Wing Resoling In Europe At Wijsman Cobblers

In Japan, they have tons of cobblers who can resole your Red Wings. During his research he stumbled upon the inspiring cobbler Fukurokujuh in Tokyo. As much as he wanted to, sending the Loggers to Japan to get them customised would be both expensive and time-consuming.

Luckily, he discovered that the Wijsman Cobblers could do the job.

Owner Ger Wijsman is one of the best cobblers in Europe. He provides his services to the entire continent and even the rest of the world. Ger had already resoled Michael’s 8118 Supersoles, so he knew how skilled Ger is.

Deciding What Should Replace the Original Vibram Outsoles

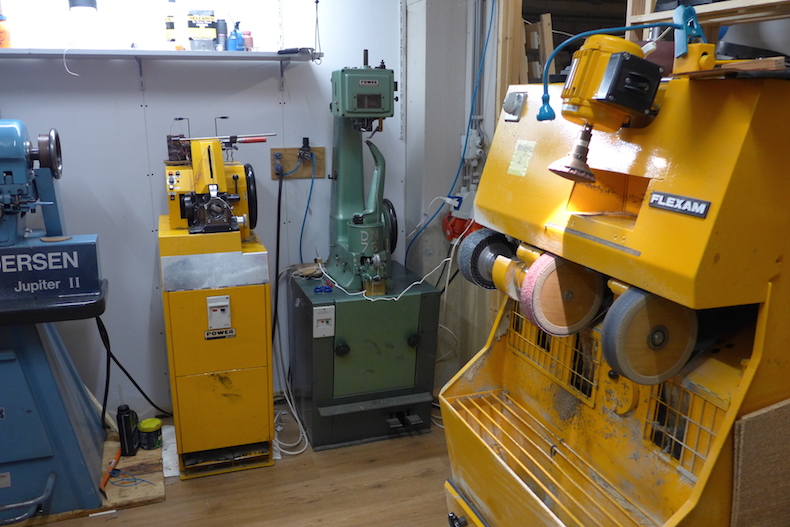

In the beginning of January, Michael went to Ger’s workshop in Delft, just outside The Hague. He showed him around his small but impressive workshop, which houses the exact same machines (or similar ones) that they have at the Red Wing plant in Minnesota. This, in combination with his high skills, makes his repairs just as good as those they can do at the original factory.

While discussing the best options for the resoling the Loggers, Ger showed Michael his stock of outsoles, heels, leather parts for layering, and so on. With such choice, colours, and materials on hand, it was a slow process. After a while, he chose what should replace the original Vibram #109 outsole of the boots:

- 2x leather layers (giving the front 50% extra thickness)

- Vibram #430 outsole

- Vibram Mini-Lug heel (matches the profile of the #430)

- US made leather stacked heel

Next Step, Getting the Job Done!

So far so good. In the second article, you will see how Ger replaced the original outsole and what the 699 Loggers ended up looking like (spoiler: amazing!).

It was inspiring to witness Ger work; just wait and see – surely, even the most knowledgeable boot enthusiasts can learned a thing or two about how Red Wings are made.

Visit his Facebook page or follow him on Instagram to get the latest updates on his work.

22 comments

allergy medication primary name allergy pills over the counter do you need a prescription

Hi there, I found your website by means of Google at the same time as searching for a similar matter, your site came up,

it looks good. I’ve bookmarked it in my google bookmarks.

Hello there, simply turned into alert to your blog thru Google, and found

that it is really informative. I am going to be careful for brussels.

I will be grateful when you proceed this

in future. Lots of people will probably be benefited out of your writing.

Cheers!

Here is my site … vpn special coupon code 2024

I like the helpful info you provide in your articles. I will bookmark your weblog and

check again here frequently. I am quite certain I’ll learn lots of new stuff right here!

Best of luck for the next!

Feel free to visit my webpage :: vpn special coupon code 2024

Very great post. I simply stumbled upon your weblog and

wished to say that I have really enjoyed surfing around your

weblog posts. In any case I’ll be subscribing in your rss

feed and I’m hoping you write again very soon!

my web-site … vpn code 2024

world pharmacy india https://indiaph24.store/# buy prescription drugs from india

india pharmacy mail order

purple pharmacy mexico price list: mexican pharmacy – mexican mail order pharmacies

https://mexicoph24.life/# reputable mexican pharmacies online

canadian pharmacy no scripts Licensed Canadian Pharmacy canadian drug pharmacy

reputable indian pharmacies https://indiaph24.store/# cheapest online pharmacy india

buy medicines online in india

buying from online mexican pharmacy: cheapest mexico drugs – mexico pharmacy

lisinopril prescription coupon: online pharmacy lisinopril – lisinopril 5 mg tablet cost

cost cheap propecia buy propecia online buying generic propecia

http://nolvadex.life/# is nolvadex legal

where can i buy zestril lisinopril cost 5mg zestoretic 25

buy misoprostol over the counter: buy cytotec over the counter – buy cytotec over the counter

http://ciprofloxacin.tech/# ciprofloxacin

https://ciprofloxacin.tech/# ciprofloxacin generic price

cipro pharmacy ciprofloxacin generic price antibiotics cipro

buy cytotec online fast delivery: Misoprostol 200 mg buy online – buy cytotec over the counter

cost of cheap propecia without dr prescription cheap propecia no prescription order generic propecia without prescription

https://lisinopril.network/# lisinopril 10 mg pill

https://ciprofloxacin.tech/# п»їcipro generic