There is nothing quite like Indigo to get the heart racing

The name of this very website, Rope Dye, comes from the method in which indigo dyestuff is applied to cotton. A hank of cotton yarns is passed through multiple dye baths, the cotton is dipped then allowed to oxidise out of the dye, then redipped and so on. Multiple times.

The many methods of indigo dying

Now, this method is most commonly associated with the production of denim. But there are a plethora of methods in which indigo is applied to the fabric and the results are as varied as the methods used. Take a look at these indigo dyed sneakers for example.

Learning from the Craftsman themselves

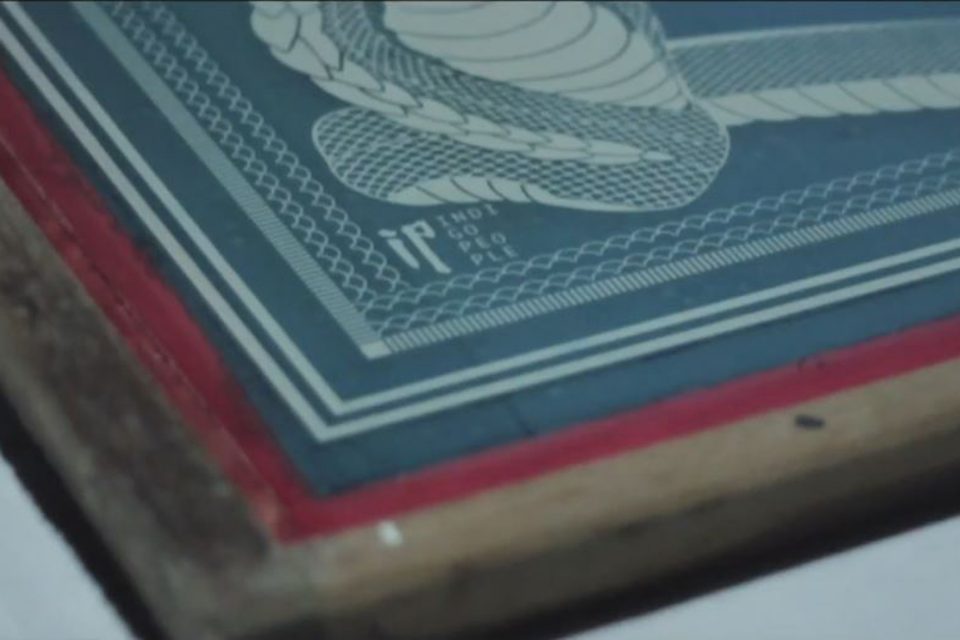

A fascinating video from our good friends over at Indigo People demonstrates yet another way in which traditional printing and dying methods are used to amazing effect, this time using the ancient art of Batik. Of course, founders Kiat and Johan throw their own take on the process.

The Batik process

Batik is a wax-resist dyeing process applied to the finished fabric. The areas on which the wax is applied stops the indigo penetrating and therefore dying that particular part of the textile. Traditional batik is either created by hand drawing with the resist wax with a tool called a ‘canting’ or by printing the melted wax with a handmade copper stamp. The trouble is, hand drawn batik is a very labour intensive process and the copper stamp is limited to a certain size.

The bandanas seen in this video feature artworks too big for either of the above methods. So they turned to another well-known printing method, Screen Printing. This is a new method was developed with their batik masters. They needed to nail down the exact consistency and composition of the waxes in order to achieve the correct thickness for screen printing.

After the wax has been applied, the cloth is then dipped piece-by-piece multiple times in natural indigo by hand, to achieve the deep indigo colour.

Afterwards, to remove the printed wax, the cloth is boiled in hot water. Once the wax is removed the printed areas regain their raw colour and the artwork appears on the textile.

The results are pretty incredible, I am sure you would agree, and props to the guys at Indigo People for creating such a beautiful video to demonstrate the process.